| Main raw Material: | Wet Mineral Fiber |

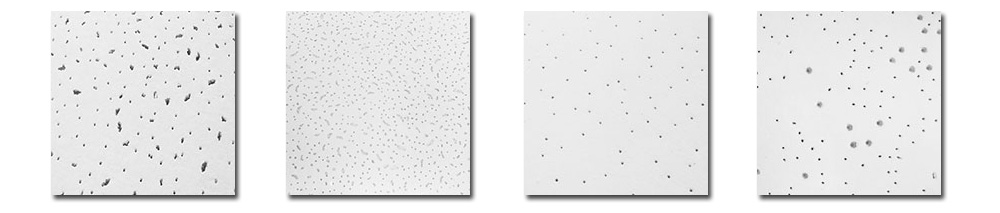

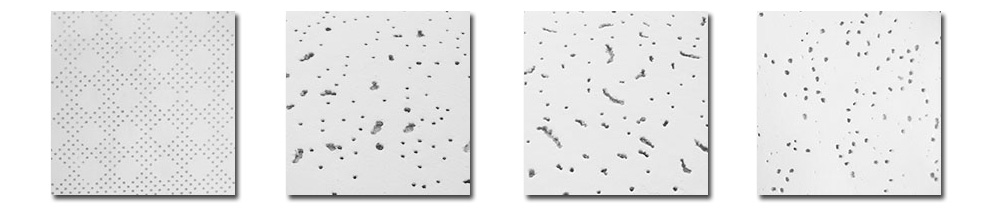

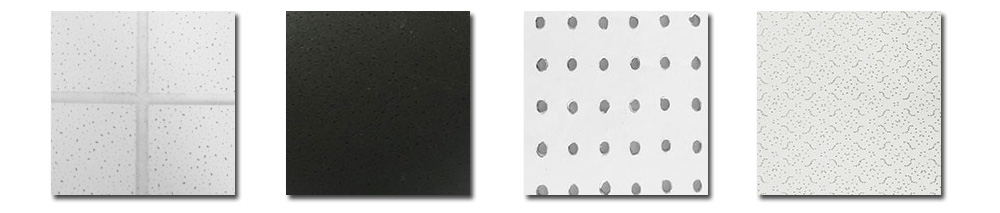

| Density: | 240kg-320kg/m3 |

| Noise Reduction coefficient: | NRC 0.55 |

| Fire Resistance: | Class B |

| Content Of Asbestos: | NON |

- 1. Excellent decorative effect.

- 2. Good heat insulation performance. The thermal conductivity of mineral wool sound-absorbing panels is very low, and it is a good thermal insulation material, which can make the room warm in winter and cool in summer, and effectively save energy for users.

- 3. Sound absorption and noise reduction. The main raw material of the mineral wool sound-absorbing board is ultra-fine mineral wool fiber with a density of 250-300Kg/m3. Therefore, it has a wealth of penetrating micropores, which can effectively absorb sound waves and reduce sound wave reflection, thereby improving indoor sound quality and reducing noise.

- 4. Safety and fire prevention.

- 5. Green environmental protection. The mineral wool sound-absorbing board does not contain harmful substances to the human body.

- 6. Moisture-proof and insulated. Because the mineral wool sound-absorbing board contains a large number of micropores and the specific surface area is relatively large, it can absorb and release water molecules in the air and adjust the indoor air humidity.

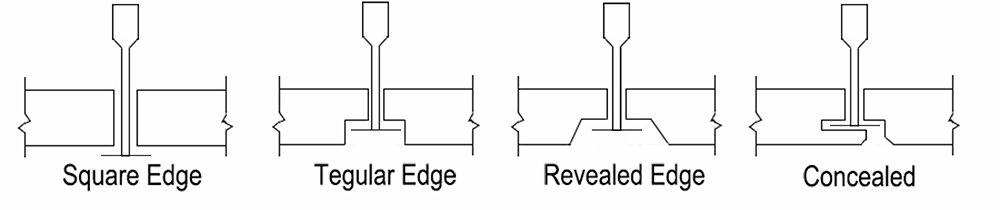

- 7. Simple cutting and easy decoration. The mineral wool sound-absorbing board can be sawed, nailed, planed, and bonded, and can be cut with a general wallpaper knife, so there is no noise during cutting. It has a variety of hoisting methods such as flat sticking, insert sticking, exposed frame, hidden frame, etc., which can combine decorative effects of different artistic styles.

- 8. Wet process, complete the whole process through pulping, Fourdrinier copying, dehydration, slitting, drying, slitting, spraying, finishing and other processes.

- 9. During the transportation of the mineral wool board, pay attention to the integrity of the packaging, moisture-proof and rain-proof, to prevent the board from being damp, which will affect the installation performance.

- 10. The mineral wool board should be lightly loaded and unloaded during the handling process. The board should be laid flat, not vertically, to avoid corner damage.